How To Perform Tap Test Aircraft Composite

Reference: AC43.13-1B Page 5-53

Note: For reference only, see actual publication for most recent version

5-105. GENERAL: Tap testing is widely used for a quick evaluation of any accessible aircraft surface to detect the presence of delamination or debonding.

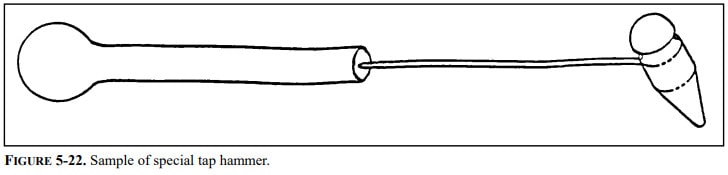

a. The tap testing procedure consists of lightly tapping the surface of the part with a coin, light special hammer with a maximum of 2 ounces (see figure 5-22), or any other suitable object. The acoustic response is compared with that of a known good area.

b. A “flat” or “dead” response is considered unacceptable. The acoustic response of a good part can vary dramatically with changes in geometry, in which case a standard of some sort is required. The entire area of interest must be tapped. The surface should be dry and free of oil, grease, and dirt. Tap testing is limited to finding relatively shallow defects in skins with a thickness less than .080 inch. In a honeycomb structure, for example, the far side bondline cannot be evaluated, requiring two-side access for a complete inspection. This method is portable, but no records are produced. The accuracy of this test depends on the inspector’s subjective interpretation of the test response; therefore, only qualified personnel should perform this test.