Rivet Spacing Aircraft Sheet Metal

Reference: AC43.13-1B Page 4-19

Note: For reference only, see actual publication for most recent version

C. Rivet Edge Distance is defined as the distance from the center of the rivet hole to the nearest edge of the sheet. Rivet spacing is the distance from the center of the rivet hole to the center of the adjacent rivet hole. Unless structural deficiencies are suspected, the rivet spacing and edge distance should duplicate those of the original aircraft structure. If structural deficiencies are suspected, the following may be used in determining minimum edge distance and rivet spacing.

(1) For single row rivets, the edge distance should not be less than 2 times the diameter of the rivet and spacing should not be less than 3 times the diameter of the rivet.

(2) For double row rivets, the edge distance and spacing should not be less than the minimums shown in figure 4-5.

(3) For triple or multiple row rivets, the edge distance and spacing should not be less than the minimums shown in figure 4-5.

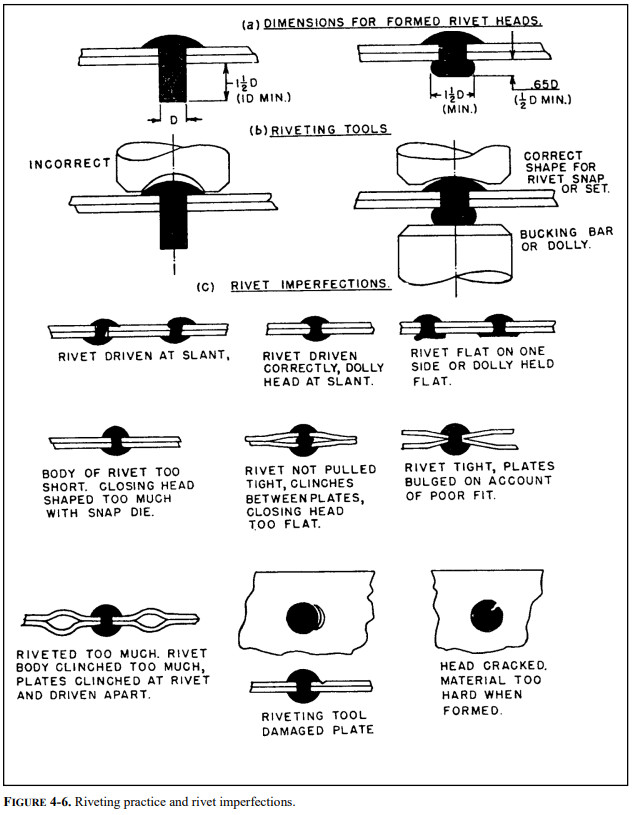

D. The 2117 Rivets may be driven in the condition received, but 2017 rivets above 3/16 inch in diameter and all 2024 rivets are to be kept packed in dry ice or refrigerated in the “quenched” condition until driven, or be reheat treated just prior to driving, as they would otherwise be too hard for satisfactory riveting. Dimensions for formed rivet heads are shown in figure 4-6(a), together with commonly found rivet imperfections.

E. When solid shank rivets are impractical to use, then special fasteners are used. Special fastening systems used for aircraft construction and repair are divided into two types, special and blind fasteners. Special fasteners are sometimes designed for a specific purpose in an aircraft structure. The name “special fasteners” refers to its job requirement and the tooling needed for installation. Use of special fasteners may require an FAA field approval.